|

|

|

|

|

|

| |

|

MW-PS-detectors

|

DENEX-GmbH develops and manufacturers multi-wire position-sensitive detectors (MW-PSD) in which

the position of neutrons or X-rays is encoded via delay-line readout.

Currently the production lines of DENEX-GmbH comprise MW-PSD-detectors with

sensitive areas ranging from 200 mm × 200 mm to 600 mm × 600 mm.

Detectors with special areas may be developed and manufactured on customer’s demand.

Detectors of all sizes may be designed for 1D- oder 2D-position-sensitive measurements with

thermal or cold neutrons (models –TN und –CN) or with hard or soft X-rays (models –HX und –SX).

They differ mainly in composition and pressure of the detection gas and the window.

Detectors for soft X-rays (models-SX) are generally designed as floating gas chambers with Ar/CO2

as detection gas, they are operated at a pressure slightly above 1 bar. (Fig. 1 and 2)

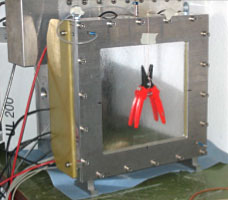

Fig.. 1: Soft X-ray radiography of a pair of pliers performed at DENEX as part of quality control of a DNX-300TN detector which was operated

for the test under floating Ar/CO2 and closed with a X-ray transparent window.

|

|

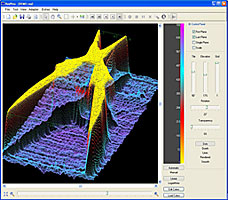

Fig. 2: 3D-representation of the radiogram measured as shown in Fig. 1 by means of the DNX-RayVisu data acquisition system.

|

These detectors may also be designed as closed chambers with thin Be-windows.

Detectors for hard X-rays (models-HX) are designed as pressure vessels. Their Xe-partial pressure is

defined such that both the detection probability at shortest wavelength and the spatial resolution are

achieved according to the customer’s specification. Neutron detectors (models-CN und -TN) are designed

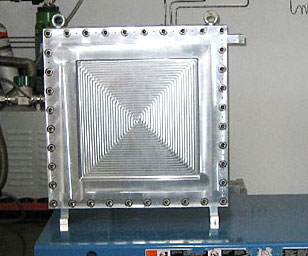

as pressure vessels, too. (Fig. 3)

|

Fig. 3: Test of a DNX-300-TN detector with neutrons at DENEX.

|

Neutrons are absorbed by 3He in the detection gas which contains

further CF4 to achieve sufficiently high position resolution. The partial pressures

of 3He and CF4 are defined such that both the position resolution and

the detection probability for cold or thermal neutrons fulfil the customer’s requirements.

Overview of main specifications of 2D-MW-PSD’s manufactured by DENEX.

Activearea: from 200 mm × 200 mm to 600 mm × 600 mm

(special dimension on customers request)

Position resolution for neutrons and hard X-rays (–TN, -CN und –HX models):

from 1 mm × 2 mm to 2 mm × 4 mm;

Position resolution for soft X-rays (SX-models):

from 0,2 mm × 1 mm to 1 mm × 2 mm;

Maximum countrate

global: ~106/s

local: ~105/s

2D-MW-PS-Detectors manufactured by DENEX are used world wide in neutron- and X-ray-diffractometers for texture- and

strain measurements, small-angle scattering, reflectometry, powder diffractometry and single crystal diffractometry.

All DENEX products are manufctured under strong quality control which comprises especially tests with X-rays and neutrons (Fig. 1 and 2).

Detector housings and beam windows of all detectors made by DENEX are designed and manufactured according to specific customer‘s demand.

Construction and manufacturing of pressure vessels meets the requirements of the European Directives.

Detectors made by DENEX-GmbH are CE-certified.

|

|

| |

|

|

©2011 DENEX-GmbH

|

|